Enersur-Suez Energy Peru is a 130MW hydroelectric plant. As the largest energy provider in Peru, Enersur also provides a substantial amount of energy to neighboring Brazil. The company wanted to add vibration analysis of their hydro generators to their protection system. Installing a permanent online system would ensure scheduled readings were regularly monitored and analyzed.

The machinery being monitored is among some of the most remote in the world, located high up in the Andes mountain range near the edge of the jungle district. After flying into Lima, Commtest's Customer Success Engineer Shane Smith and local channel partner Marco Ortiz drove 300km up the steep and often winding road. 'Altitude sickness was a problem,' says Smith 'but the mountains were incredible'. The facility's inherent lack of accessibility was a key driver in the decision to install a system that could remotely monitor Ensersur's machinery and transmit the data off-site.

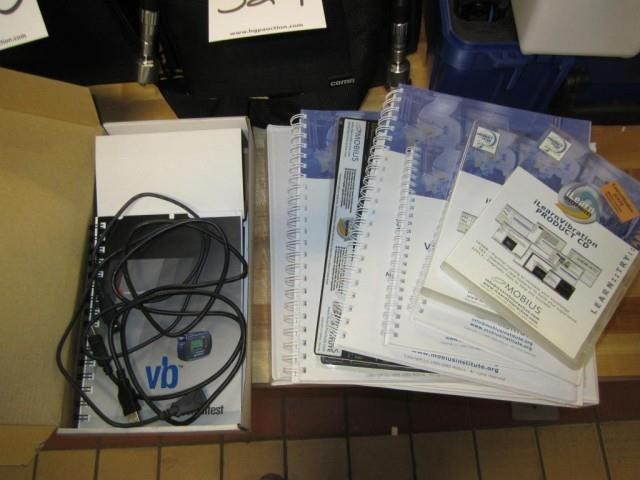

Two 32 channel vbOnline systems were set up to take 39 readings from buffered outputs of a Bently Nevada 3500 rack. These signals correspond to 18 radial proximity probes, 6 axial probes, 3 keyphasor® and 12 airgap sensors. All sensors were pre-installed in three hydro generators of 44.5MW each.

Reliable seismic readings were critical. Eighteen low frequency sensors with dual output (measuring vibration and temperature) were installed, in a radial direction and aligned with the probes. The first vbOnline system was installed to take measurements from the seismic sensors, making sure that not only the vibration from the shaft is taken, but also vibration measurements from the journal bearing structure were collected.

The second vbOnline system was installed to take measurements from 12 critical oil pumps and 2 air compressors, connecting to 32 general purpose accelerometers distributed over the oil pumps and compressors. These readings are taken twice a day. Both vbOnline systems combine with Commtest's award winning Ascent® software, providing remote diagnostics and analysis where it is most needed.

About Commtest Instruments Ltd

Commtest is the world leading designer of machinery health information systems. We're passionate about creating simple, intelligent systems that give our customers access to the information they need to keep their machinery operating in optimum condition and meeting corporate goals. Commtest has offices in the USA, China, Dubai and New Zealand.

Press Release: Commtest

Commtest Instruments VB 2000 saves Metso Minerals months onproduct testing

Christchurch, New Zealand, 9September 2004 - Since Metso Minerals incorporated theCommtest vibration analyser system into their testprogramme, they have more than justified their investment.They have been able to achieve, and pass onto theircustomers, significant product design enhancements thatincrease performance and reliability, and reduce costs allround.

Metso Minerals, based in Matamata NewZealand, designs, manufactures and exports up to 23 tonneBarmac (Vertical Shaft Impacter) VSI crushers that canpulverise between 10 and 2080 tonnes of rocks per hour intobite-sized smithereens. With such formidable force theslightest structural imbalance can cause almost as muchdamage to the machine itself, as it does to the rocks itpunishes.

- About Commtest Instruments Ltd Commtest is the world leading designer of machinery health information systems. We're passionate about creating simple, intelligent systems that give our customers access to the information they need to keep their machinery operating in optimum condition and meeting corporate goals.

- Solidus offers a family of STICOMM instruments providing a range of serial and parallel device testing configurations with increased tester resources and flexibility, depending on your test needs. STICOMM01 Features. MUX 12 pins of tester resources to 4 DUTs. Clock Buffering. VDD Buffering. LF Generation.

- Dear All, please I have problem with Ascent Software (Commtest & Bently Nevada), but the software not start in computer, the problem started suddenly, it was working normally more than 2 years. But now, it can not start. Please, If someone has had similar problem like this, help me.

- The AMS 2140 Machinery Health Analyzer takes vibration data and analysis measurements to the next level. It features simultaneous four-channel plus phase data collection and unique peak detection capabilities for the earliest indication of bearing and gearbox degradation.

12 Ascent Commtest Ascent is a vibration analysis System available in three (New Zealand) system for monitoring the main complexity levels. Level 3 includes.

While maintenance is critical and repairsare inevitable, Metso design engineers are discovering theadvantage of using Commtest VB 2000 to fine-tune prototypesand minimise wear and tear on machinery.

Rock OnRock For Crushing Results

Invented in New Zealandthe Barmac VSI is globally unique due to its power-savingcrushing process. Unlike other types of crusher, which usemetallic parts to crush rocks, the Barmac uses rocks fedinto the machine to crush others through high velocityimpact. Rocks entering the rotating rotor are hurled at highspeeds into the chamber and smashed against other rocksfalling through the machine. Adjusting the rotor speedcontrols the size and shape of the reduced product desiredfor the application.

The Barmac has found a home inmany niche applications offering lower power consumption, upto 50% less wear and tear to metal parts, and increasedproduct throughput by up to 30% over other technology.

The machines are used in over 3000 quarrying and mineralprocessing sites worldwide. Customers include aggregate andsand processing plants, industrial mineral sites from cementclinker to diamond mines, to waste and recycling sites.

In such critical and dangerous environments reliabilityand productivity is key, and customers can ill afford tohave any component of their business out of operation and inneed of costly repair. Therefore, a constant challenge forMetso design engineers is building a crusher that canwithstand the rock-pounding abuse, is easy to maintain,cost-effective to produce and operate, and requires minimaldowntime.

Using Vibration Analysis To AvoidResonance Damage

The design of Metso machines hasadvanced considerably over the years and they are now usedin more applications and run at a wider range of speeds thanever before.

'We used to employ consultants toperform vibration tests on new prototypes as well as onproblematic machines. But this was proving a costly exerciseand didn't allow the flexibility or convenience ofexperimenting with and analysing a variety of tests fordetailed design and modification,' said David Kenny, R&DEngineer at Metso Minerals.

'We started doing ourown tests three years ago after an incident where we werebaffled as to what had caused a cracked shaft on one of ourmachines. We were amazed when a consultant established thefault straightaway using Commtest's vibration analysisequipment in a bump test. He found that, at a certain speed,the resonance - or natural frequency - of the machine wasthe root cause of the problem. The solution was to adjustthe rotor speed above or below its natural frequency, and wehad no more problems.'

Excited with this fast andaccurate analysis Metso decided to invest in an in-housesolution. They looked at what their suppliers andconsultants were using and chose to purchase the Commtest VB2000.

'Compared with the cost of employing consultantsevery time we looked at a design change, and againstcompeting products at almost three times the price, it waseasy to justify to management the investment in the VB 2000vibration analysis system,' explained David. Free download manycam driver.

Enhanced Product Design with the VB 2000

SinceMetso purchased the Commtest VB 2000 design engineers havebeen able to apply regular condition monitoring tests to allnew prototypes.

The company has a range of sevenBarmac machines on the market, and continually improves themto perform better in existing applications, as well as newapplications that are developed. They have also had to dealwith more and more customers using variable speed drivesthat allow them to quickly change the product required thatday.

Traditionally these machines have belts andpulleys to change increment speeds, which wouldn't change sooften. Having more customers using variable speed drives hascreated a new set of problems and made the design morecomplex,' said David.

'We use the VB 2000 to findthe natural frequencies in the speed range that each machineprototype is rated for. This enables us to make the wholefrequency range safe to work and eliminates any possibilityof excessive vibration that could cause surprisebreakdowns.'

The ability to do these teststhemselves allows Metso instant flexibility, speed andconvenience to adapt the structural design of their machinesaccordingly.

How Commtest's VB 2000 Saves Months onProduct Testing and Analysis

Without Commtest's VB2000 vibration analysis equipment it would have taken Metsoup to four months to test and determine at which of the tenspeeds the resonance might occur and cause damage to aprototype. Now it only takes one day of tests per prototypeto locate where the problems are likely to be. Download conrad electronic usb devices driver.

'Theolder Barmac machines were over-engineered with highersafety margins, and required more steel and labour thanneeded to operate without resonance. To save on steel andget the same results we needed to do better testing anddesign the products more effectively,' explained David.

'To meet customer demand for advanced machinery, we'vehad to learn how to work smarter, not harder. The VB 2000gives us results we can use to maximise the design of newprototypes for increased reliability and performance, whileminimising steel and labour costs.'

'Throughout therelationship Commtest have guided us well, and providedexcellent customer service and support. The VB 2000 hasproved very cost-effective.'

About CommtestInstruments (www.commtest.com)

Commtest Instrumentsis a privately owned company, headquartered in ChristchurchNew Zealand, that specialises in creating precisionmonitoring and analysis solutions that enable companies todiagnose a machine's operating condition quickly andcost-effectively. With an established channel footprint in24 countries, Commtest generates 98% of its revenue fromoverseas earnings with major customers in forestry,printing, paper & pulp, rail, transit and defence. Thecompany achieved top recognition for its export sales in theNZTE and NZ Business 2003 survey of New Zealand's 100 mostsuccessful exporters.

Drivers Commtest Instruments Inc

The Commtest VB Series are‘intelligent maintenance solutions' designed to provideprecision vibration, monitoring and analysis of rotatingmachinery at a fraction of the cost of comparable packages.Customers can expect up to 35% costs savings when they makea full changeover from preventative maintenance to apredictive maintenance system, and achieve reduction inplant power consumption by 10% or more.

About MetsoMinerals (Matamata) Limited

The AVerMedia team is committed to keeping our customers informed on the latest changes and developments. Thank you for your continued support and understanding during these times. Windows device driver information for PCI MIMO Wireless LAN Card. The PCI MIMO Wireless LAN Card by Gigabyte is capable of delivering wireless access to users' desktop computers, and sharing and connecting their broadband connection, as well as their network resources. This WLAN card can increase the wireless. AVerMedia AVerMedia EYES Pro Driver. AVerMedia AVerMedia EYES Pro Driver for Windows. Drivers avermedia network & wireless cards. Date: 2019-06-03: Version: 1.1.1045 (Beta) OS: Linux nvidia-desktop 4.9.140-tegra: Description: Linux4Tegra R32.1 for NVIDIA Tegra X2 platform. To download the driver & other version driver. AVerMedia does not guarantee that all the drivers provided from this website will meet requirements of the users' current equipments or devices and in no events.

Drivers Commtest Instruments Online

Metso Minerals(Matamata) Ltd, based in Matamata, New Zealand, manufacturesthe Barmac Vertical Shaft Impact (VSI) rock crusher used inthe global quarrying and minerals processing industries. The company was established in 1968 and became part of theMetso Corporation in 2001. They now employ nearly 70 peopleand exports 90% of its products to the network of MetsoMinerals distributors around the world.

Drivers Commtest Instruments

While maintenance is critical and repairsare inevitable, Metso design engineers are discovering theadvantage of using Commtest VB 2000 to fine-tune prototypesand minimise wear and tear on machinery.

Rock OnRock For Crushing Results

Invented in New Zealandthe Barmac VSI is globally unique due to its power-savingcrushing process. Unlike other types of crusher, which usemetallic parts to crush rocks, the Barmac uses rocks fedinto the machine to crush others through high velocityimpact. Rocks entering the rotating rotor are hurled at highspeeds into the chamber and smashed against other rocksfalling through the machine. Adjusting the rotor speedcontrols the size and shape of the reduced product desiredfor the application.

The Barmac has found a home inmany niche applications offering lower power consumption, upto 50% less wear and tear to metal parts, and increasedproduct throughput by up to 30% over other technology.

The machines are used in over 3000 quarrying and mineralprocessing sites worldwide. Customers include aggregate andsand processing plants, industrial mineral sites from cementclinker to diamond mines, to waste and recycling sites.

In such critical and dangerous environments reliabilityand productivity is key, and customers can ill afford tohave any component of their business out of operation and inneed of costly repair. Therefore, a constant challenge forMetso design engineers is building a crusher that canwithstand the rock-pounding abuse, is easy to maintain,cost-effective to produce and operate, and requires minimaldowntime.

Using Vibration Analysis To AvoidResonance Damage

The design of Metso machines hasadvanced considerably over the years and they are now usedin more applications and run at a wider range of speeds thanever before.

'We used to employ consultants toperform vibration tests on new prototypes as well as onproblematic machines. But this was proving a costly exerciseand didn't allow the flexibility or convenience ofexperimenting with and analysing a variety of tests fordetailed design and modification,' said David Kenny, R&DEngineer at Metso Minerals.

'We started doing ourown tests three years ago after an incident where we werebaffled as to what had caused a cracked shaft on one of ourmachines. We were amazed when a consultant established thefault straightaway using Commtest's vibration analysisequipment in a bump test. He found that, at a certain speed,the resonance - or natural frequency - of the machine wasthe root cause of the problem. The solution was to adjustthe rotor speed above or below its natural frequency, and wehad no more problems.'

Excited with this fast andaccurate analysis Metso decided to invest in an in-housesolution. They looked at what their suppliers andconsultants were using and chose to purchase the Commtest VB2000.

'Compared with the cost of employing consultantsevery time we looked at a design change, and againstcompeting products at almost three times the price, it waseasy to justify to management the investment in the VB 2000vibration analysis system,' explained David. Free download manycam driver.

Enhanced Product Design with the VB 2000

SinceMetso purchased the Commtest VB 2000 design engineers havebeen able to apply regular condition monitoring tests to allnew prototypes.

The company has a range of sevenBarmac machines on the market, and continually improves themto perform better in existing applications, as well as newapplications that are developed. They have also had to dealwith more and more customers using variable speed drivesthat allow them to quickly change the product required thatday.

Traditionally these machines have belts andpulleys to change increment speeds, which wouldn't change sooften. Having more customers using variable speed drives hascreated a new set of problems and made the design morecomplex,' said David.

'We use the VB 2000 to findthe natural frequencies in the speed range that each machineprototype is rated for. This enables us to make the wholefrequency range safe to work and eliminates any possibilityof excessive vibration that could cause surprisebreakdowns.'

The ability to do these teststhemselves allows Metso instant flexibility, speed andconvenience to adapt the structural design of their machinesaccordingly.

How Commtest's VB 2000 Saves Months onProduct Testing and Analysis

Without Commtest's VB2000 vibration analysis equipment it would have taken Metsoup to four months to test and determine at which of the tenspeeds the resonance might occur and cause damage to aprototype. Now it only takes one day of tests per prototypeto locate where the problems are likely to be. Download conrad electronic usb devices driver.

'Theolder Barmac machines were over-engineered with highersafety margins, and required more steel and labour thanneeded to operate without resonance. To save on steel andget the same results we needed to do better testing anddesign the products more effectively,' explained David.

'To meet customer demand for advanced machinery, we'vehad to learn how to work smarter, not harder. The VB 2000gives us results we can use to maximise the design of newprototypes for increased reliability and performance, whileminimising steel and labour costs.'

'Throughout therelationship Commtest have guided us well, and providedexcellent customer service and support. The VB 2000 hasproved very cost-effective.'

About CommtestInstruments (www.commtest.com)

Commtest Instrumentsis a privately owned company, headquartered in ChristchurchNew Zealand, that specialises in creating precisionmonitoring and analysis solutions that enable companies todiagnose a machine's operating condition quickly andcost-effectively. With an established channel footprint in24 countries, Commtest generates 98% of its revenue fromoverseas earnings with major customers in forestry,printing, paper & pulp, rail, transit and defence. Thecompany achieved top recognition for its export sales in theNZTE and NZ Business 2003 survey of New Zealand's 100 mostsuccessful exporters.

Drivers Commtest Instruments Inc

The Commtest VB Series are‘intelligent maintenance solutions' designed to provideprecision vibration, monitoring and analysis of rotatingmachinery at a fraction of the cost of comparable packages.Customers can expect up to 35% costs savings when they makea full changeover from preventative maintenance to apredictive maintenance system, and achieve reduction inplant power consumption by 10% or more.

About MetsoMinerals (Matamata) Limited

The AVerMedia team is committed to keeping our customers informed on the latest changes and developments. Thank you for your continued support and understanding during these times. Windows device driver information for PCI MIMO Wireless LAN Card. The PCI MIMO Wireless LAN Card by Gigabyte is capable of delivering wireless access to users' desktop computers, and sharing and connecting their broadband connection, as well as their network resources. This WLAN card can increase the wireless. AVerMedia AVerMedia EYES Pro Driver. AVerMedia AVerMedia EYES Pro Driver for Windows. Drivers avermedia network & wireless cards. Date: 2019-06-03: Version: 1.1.1045 (Beta) OS: Linux nvidia-desktop 4.9.140-tegra: Description: Linux4Tegra R32.1 for NVIDIA Tegra X2 platform. To download the driver & other version driver. AVerMedia does not guarantee that all the drivers provided from this website will meet requirements of the users' current equipments or devices and in no events.

Drivers Commtest Instruments Online

Metso Minerals(Matamata) Ltd, based in Matamata, New Zealand, manufacturesthe Barmac Vertical Shaft Impact (VSI) rock crusher used inthe global quarrying and minerals processing industries. The company was established in 1968 and became part of theMetso Corporation in 2001. They now employ nearly 70 peopleand exports 90% of its products to the network of MetsoMinerals distributors around the world.

Drivers Commtest Instruments

Drivers Commtest Instruments Crossword Clue

- Ends-

© Scoop Media

Drivers Commtest Instruments Definition

Join the Scoop Citizen Community

20 years of independent publishing is a milestone, but your support is essential to keep Scoop thriving. We are building on our offering with thedig.nz our new In-depth Engaged Journalism platform. Now, more than ever sustainable financial support of the Scoop Foundation for Public Interest Journalism will help to keep these vital and participatory media services running.Find out more and join us:

Become a memberFind out more